What We Stand For

More about the companyDigitalization

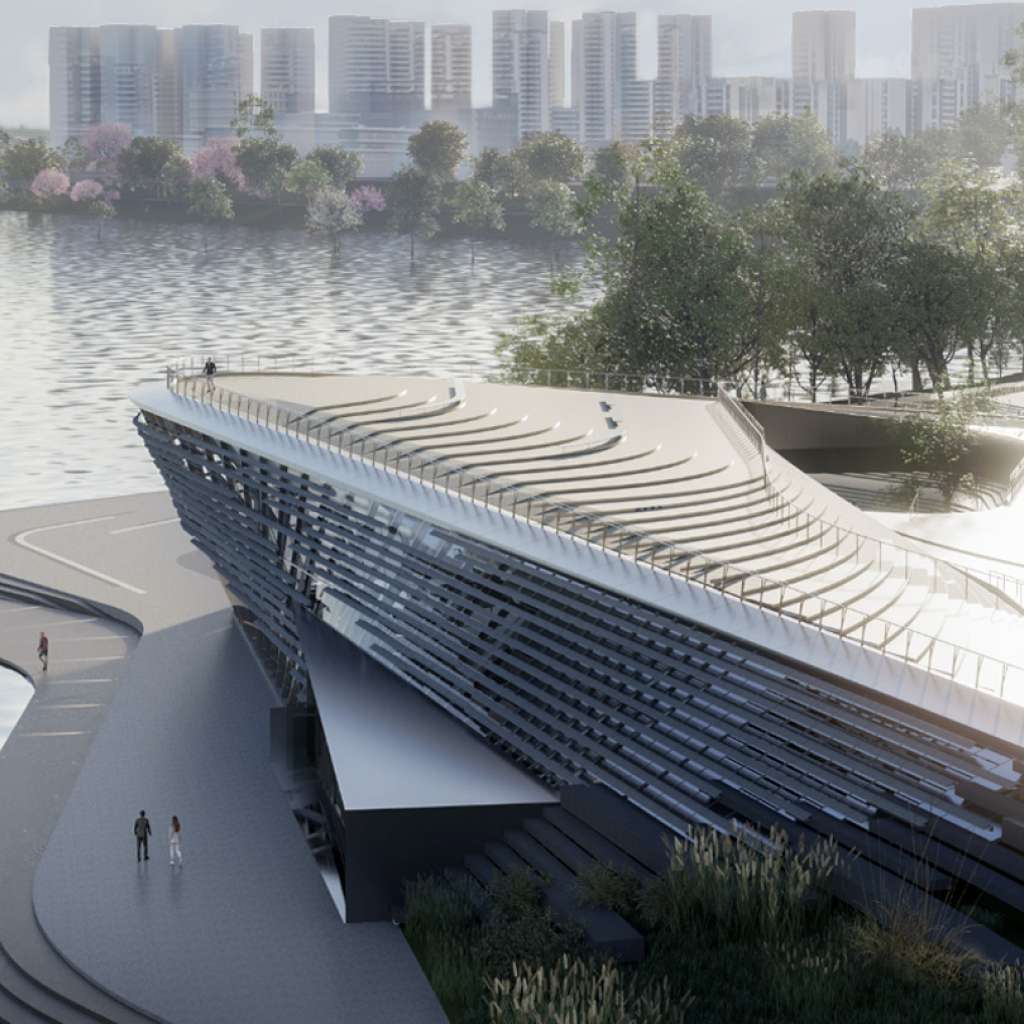

We drive digital transformation in the Architecture, Engineering, Construction, and Operation industry by empowering all users in every phase of the building lifecycle with best-in-class software solutions.

Open Standards

We are an advocate for open industry standards & OPEN BIM to ensure that our customers are always able to use the best software solutions for their individual needs.

Customer Focused

Our unique structure gives our brands the entrepreneurial freedom to develop innovative, customer-focused solutions, with the added benefit of cross-collaboration and knowledge-sharing for best-in-class tools.

A

A  E

E  C

C  O

O