Global supply chains – local challenges

Approaches to solving the shortage of materials in the construction industry

Author

Eva Herrmann

Architect and freelance journalist with focus on communication the culture of building/architecture.

This article belongs to the collection Quality & Efficiency

To the topic pagefiller content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

filler content text filler content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content textfiller content text

"The world is in a rush for raw materials" read the headline on a major German daily newspaper in August 2021. But while analysts are rubbing their hands, the current surge in raw material prices is upsetting global economic cycles. There is a shortage of nearly everything: electronic components, plastics, and lumber, but also insulation material, metal, even soap and cleaning agents are affected. A devastating situation, but the shortage also offers opportunities for the construction industry.

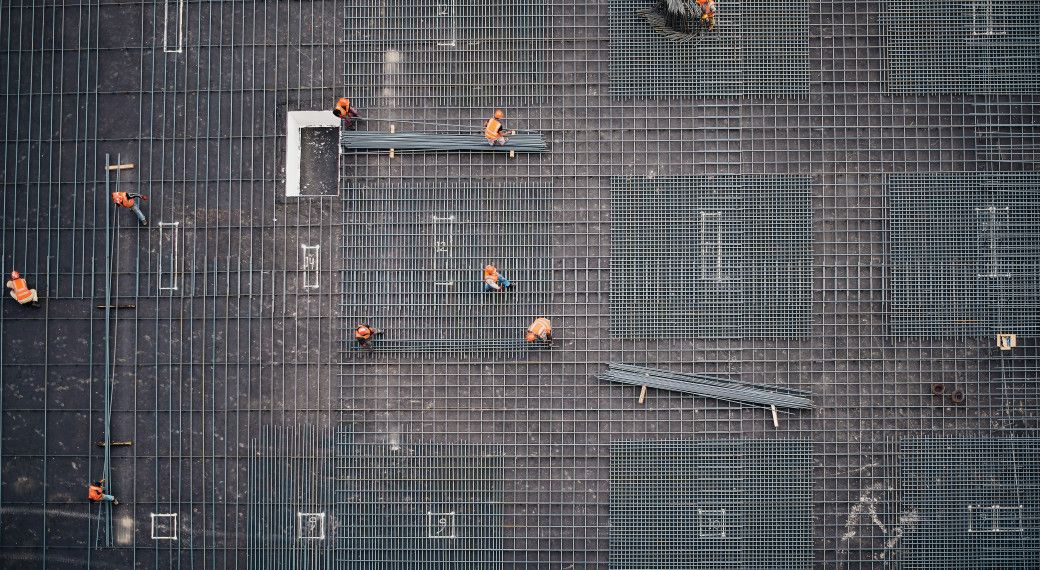

Demand for raw materials is strongly influenced by the construction and manufacturing sectors. A recent calculation by the German Construction Industry Association (Hauptverband der Deutschen Bauindustrie e.V.) summarizes the developments in figures: the price of reinforcing steel bars in June 2021 was 62.3% higher than in June 2020, while the price of bitumen was 56.7% higher. Year-on-year, the average price of construction timber is 58.8% higher, and the producer price of polystyrene insulation boards has risen 27.3% since December 2020. The peak of the bullish market was the price of lumber, which tripled within a few months and became traded like gold and oil. With minor variations, the magnitudes of the price development for building materials are similar worldwide.

The reasons for the shortage of materials and the price increases are many. One temporary phenomenon is the restricted extraction and production of raw materials during the Covid-19 lockdown. Productivity has not yet returned to pre-pandemic levels, despite the pickup in the economy. In addition, there are bottlenecks in transportation and gaps in the global supply chain due to a lack of containers or production facility outages. But government stimulus programs in China and the U.S. are also affecting global trade. While China was recently a major exporter of low-cost steel products, rising demand in the construction and automotive sectors is now turning the country into an importer and has resulted in a ban on scrap steel exports. This is also reflected in the availability of plastics, which are mostly produced in Asia and then imported into Europe. Whereas previously there was talk of sophisticated just-in-time deliveries, the call for a national raw materials strategy for building materials is making the rounds.

Necessity is the mother of invention. And it offers the opportunity for a long overdue transformation in the construction industry – because today's linear economic model is not sustainable. The principle of the circular economy, on the other hand, can conserve valuable resources. Instead of disposing the product at the end of its useful life, the raw materials it contains are reused and, in the best case, undergo upcycling. But what materials are construction elements and components made of? How are they assembled and with what effort can they be separated and returned to the cycle? How are supply and demand organized? Digitalization simplifies these complex processes; software solutions enable a more transparent information structure. If it was previously not economical to reuse material, well thought-out material cycles can lead to savings along the life cycle of buildings – to the benefit of all through a sustainable value chain.

Digitalization is also a lever for greater resource efficiency. Transparency, flexibility, and information quality are improved by software solutions, digital applications, and intuitive technologies. Whether it's resource-saving construction methods such as lightweight or hybrid designs, production processes such as 3D printing, or the use of Big Data or its hive intelligence, as well as digital twins and virtual reality – the time for waste is over. The sustainable use of materials through innovative technologies and transparent material cycles must be the answer to the material crisis. This is the only way to actively influence the dependence on global material cycles and the resulting speculation in the future. The positive influence on the CO2 balance and energy savings through reuse and local transport routes is a beneficial and, at the same time, enormously important side effect.

Register For Our Newsletter Today

Stay up-to-date and be the first to know about our latest article releases on Nemetschek Topics & Insights.