Facts

Location

Hamburg

Nemetschek Group Brands

ALLPLAN

Solibri

Sector

Infrastructure

Client

Hamburg Port Authority

Technology used

Allplan BIMplus

Solibri

Built in 1974, the Köhlbrand Bridge is Germany’s second-longest road bridge as well as one of its busiest. The cable-stayed bridge serves around 36,000 vehicles per day, thus playing a crucial role in the local economy. “The HPA is the bridge’s operator, so we wanted to find a way to maintain and operate the bridge more effectively. After recognizing the potential of digital twins to assist with this goal, we initiated the smartBRIDGE Hamburg project in 2019”, says Jens Meier, CEO of HPA. Using OPEN BIM, ICF data exchange formats, and the BIM Collaboration Format (BCF), Allplan and Solibri helped make this aspiration a reality.

Building Together with BIM

The age of the bridge and the amount of daily traffic it supported meant that continuous real-time monitoring was the best way to identify repairs and minimize disruption to traffic. Without this, issues could go undetected and lead to larger problems that could affect the safety and operation of the bridge.

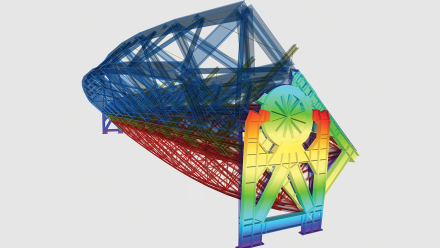

A BIM model of the bridge was designed from scratch, as there were no existing models due to the age of the bridge. Multiple BIM applications were used for this, including Allplan, which enabled a highly detailed model of the bridge to be created. The entire bridge structure as well as its individual components could be clearly visualized in the comprehensive model that was created.

A Practical Example of a Digital Twin

With a solid basis for their digital twin set up, the Hamburg Port Authority were able to then integrate IoT sensor data and traditionally collected bridge inspection and maintenance data with their bridge model. Over 500 IoT sensors were connected to a digital sensor in the bridge model, providing the real-time monitoring that the Hamburg Port Authority desired and automatically issuing alerts if problems are detected. Both sets of data were then made available to the asset management system of the bridge, enabling predictive maintenance to be better planned and executed.

César Flores-Rodríguez, Chief Division Officer Operate & Manage und Business Unit Digital Twin.

“Often, it is difficult to find examples of digital twins being implemented fully, as they are intended to be. The smartBRIDGE Hamburg project shows the practical application of a digital twin in a real-life context, demonstrating just how valuable digital twin technology can be. Our portfolio of OPEN BIM solutions means that Nemetschek can support this emerging technology across the entire AEC/O value chain”

Planning Ahead with Insight-led Decisions

As well as the continuous monitoring of the bridge structure, the digital twin also enables various simulations to be undertaken. This way, when the Hamburg Port Authority have detected a problem, they can also test different solutions and scenarios and assess the results prior to implementation. For an infrastructure asset as essential as the Köhlbrand Bridge, these insights are vital for ensuring safety and minimizing disruption. Clearly, a digital twin has been the key to ensuring these two goals are met, and will no doubt play an instrumental role in enabling data-driven operation and maintenance of the bridge for the foreseeable future.